A big Hello to all Motorbike and Car enthusiasts !!

I am Ishan Dev , the new Technical In-charge for the budding blog, Engine Freak.

I am here to share some information about Automobiles (Cars and Motorbikes) to endow our readers with some in-depth knowledge of the same, so that you guys can atleast stop the mechanics and the Service Centre crooks from making a fool of you, and if you want, a lot more. This is my first article here, so I would like to start with the basics of an engine, or should I say the Internal Combustion Engine (ICE), for what it is called in the Automobile industry.

Overview

Engines can be of many types.. Any machine which can convert one form of energy into another to do some useful work is called an engine. It may be a mechanical, electrical, thermal, computational, or any other type of engine.

Our concern here is only the thermal engine that converts thermal energy into mechanical energy. There are two types of thermal engines, the External combustion engine and the Internal combustion engine. The difference between them is the way of burning fuel.

As you may guess, in external combustion engine, the fuel is burned outside of the engine to warm/change the state of the working fluid and then use it to do some kind of work, for example, pushing a piston or rotating a turbine.

In the Internal combustion engine (ICE), the fuel is burned inside of a closed chamber, known as Combustion Chamber, from where it gets its name..

There are other types too, but they are far from what we are concerned about. Here, our discussion is limited to 4-stroke ICE only.

Combustion Events

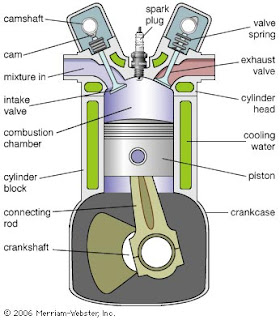

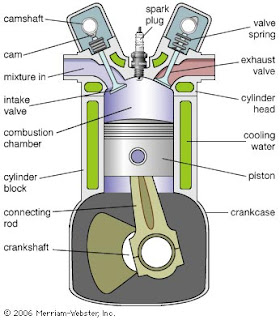

An Engine (I will use it in place of ICE in this article) consists a lot of parts to easily confuse an average Joe, but then it isn't so difficult either.

Like we have the Motherboard in a PC, the engine has an Engine Block in which most of the parts of the engine are fitted. The main part of the engine, as discussed above, is the combustion chamber. Here the fuel(mostly petrol or diesel) is burned in a 4-stroke cycle.

Now you may be thinking, “What is a 4-Stroke Cycle..???”

4-stroke engines work in a cycle of 4 steps, namely, Induction stroke, Compression stroke, Combustion(Power) stroke and at last, Exhaust stroke, where a stroke is equal to half a rotation of engine or one up/down motion of the piston. From here it gets its name, 4-stroke. These are performed repeatedly in same sequence, so it is called a cycle. It is also called the Otto cycle in the name of Nikolaus Otto, who built the first 4-stroke engine.

To help the engine perform these tasks, Intake and Exhaust valves(mechanically operated doors) are provided in the combustion chamber. They are opened and closed by a cam-shaft with the help of rocker-arms or push-rods, depending on the technology used. Let us see how all these things happen.

INTAKE STROKE

The first step is the Intake stroke. In this stroke, the Intake valve(s) is(are) opened and the Charge, a stoichiometric mixture ( theoretically 14.7:1, 12.5:1 in real world, for petrol ) of air and fuel is sent into the combustion chamber through it. The charge can be prepared by using a carburetor or a fuel injection system and controlled by using the throttle(accelerator). The air is taken from the atmosphere through an air-filter. We will present a separate article for this topic in a few days.

COMPRESSION STROKE

The second step is the Compression stroke. The Intake valve(s) is/are closed and charge is compressed by the piston, normally in the ratio 8 to 10:1 for petrol engines and 14 to 22:1 for diesel engines.

COMBUSTION STROKE

The third step is the Combustion stroke. There is a spark plug in the combustion chamber of engine which ignites the compressed charge and creates a blast, which pushes down the piston. The spark plug gets it electricity (upto 35000 volts) from the ignition coil which is controlled by an ignition system. Usually CDI(Capacitor Discharge Ignition) or TCI(Transistor Controlled Ignition) ignition systems are used in carbureted Motorbikes & Cars, whereas ECU (Engine Control Unit) is used in Fuel Injected Motorbikes & Cars. This is the actual step in which we get power from the engine. That’s why it is also called the power stroke.

EXHAUST STROKE

The fourth and last step is the Exhaust stroke in which the exhaust valve(s) is/are opened by the cam-shaft and the exhaust gases, which were created during power stroke, are expelled out of the engine through it and they pass through a platinum coated Catalytic Convertor, which converts these poisonous gases into other not-so-harmful compounds.

As you may have noticed, till now only an up-down motion of the piston is generated. This linear motion needs to be converted into rotational motion to drive the vehicle. Let us see how…

Motion Conversion

The piston is connected to a Con-Rod(short form of connecting rod) which in turn is connected to the crank-shaft. The crank-shaft is a device which converts the linear up-down motion of the piston into a usable rotational motion.

The Crank-shaft is connected to a Clutch system, which then connects to transmission (gear) system, with a reduction ratio of normally 3:1. This means that the transmission system rotates at about one-third of the speed of engine (rpms). This is called the Primary Reduction. A clutch is a device which can engage or dis-engage the transmission, as required by the rider/driver, by using a system of clutch plates(generally 4 or 5), Pressure plates(generally 3 or 4) and some springs (generally 4).

Each Pressure plate is sandwitched between two Clutch plates. It can be actuated either hydraulically or by using cables. The transmission converts the rotation for more torque (lower gears) or more power (higher gears) and provides the output through output shaft. As all the internal components of an engine are constantly sliding on each other, an engine oil is put inside the engine case for lubrication.

In motorcycles, a sprocket is connected to this output shaft, which in turn, is connected an another sprocket(usually larger) at the rear wheel. This means that the rear wheel rotates at a further reduced speed. This is called the Secondary Reduction. Normally it is around 3:1. This means that the rear wheel rotates at about one-third of the speed of the output shaft.

In a car, the output shaft connects to the front two, rear two or all the four wheels using a differential system (we will cover it later on). The differential reduces the rotational speed of output shaft and prevents the wheels of any one side from slipping while the car is taking a turn.

And that’s how an engine converts thermal energy into the car’s movement.

I hope you guys liked and understood my words. Feel free to express any questions that are in your mind and also help us to make this blog better.

Article by Ishan Dev

I am Ishan Dev , the new Technical In-charge for the budding blog, Engine Freak.

I am here to share some information about Automobiles (Cars and Motorbikes) to endow our readers with some in-depth knowledge of the same, so that you guys can atleast stop the mechanics and the Service Centre crooks from making a fool of you, and if you want, a lot more. This is my first article here, so I would like to start with the basics of an engine, or should I say the Internal Combustion Engine (ICE), for what it is called in the Automobile industry.

Overview

Engines can be of many types.. Any machine which can convert one form of energy into another to do some useful work is called an engine. It may be a mechanical, electrical, thermal, computational, or any other type of engine.

Our concern here is only the thermal engine that converts thermal energy into mechanical energy. There are two types of thermal engines, the External combustion engine and the Internal combustion engine. The difference between them is the way of burning fuel.

As you may guess, in external combustion engine, the fuel is burned outside of the engine to warm/change the state of the working fluid and then use it to do some kind of work, for example, pushing a piston or rotating a turbine.

In the Internal combustion engine (ICE), the fuel is burned inside of a closed chamber, known as Combustion Chamber, from where it gets its name..

There are other types too, but they are far from what we are concerned about. Here, our discussion is limited to 4-stroke ICE only.

Combustion Events

An Engine (I will use it in place of ICE in this article) consists a lot of parts to easily confuse an average Joe, but then it isn't so difficult either.

Like we have the Motherboard in a PC, the engine has an Engine Block in which most of the parts of the engine are fitted. The main part of the engine, as discussed above, is the combustion chamber. Here the fuel(mostly petrol or diesel) is burned in a 4-stroke cycle.

Now you may be thinking, “What is a 4-Stroke Cycle..???”

4-stroke engines work in a cycle of 4 steps, namely, Induction stroke, Compression stroke, Combustion(Power) stroke and at last, Exhaust stroke, where a stroke is equal to half a rotation of engine or one up/down motion of the piston. From here it gets its name, 4-stroke. These are performed repeatedly in same sequence, so it is called a cycle. It is also called the Otto cycle in the name of Nikolaus Otto, who built the first 4-stroke engine.

To help the engine perform these tasks, Intake and Exhaust valves(mechanically operated doors) are provided in the combustion chamber. They are opened and closed by a cam-shaft with the help of rocker-arms or push-rods, depending on the technology used. Let us see how all these things happen.

INTAKE STROKE

The first step is the Intake stroke. In this stroke, the Intake valve(s) is(are) opened and the Charge, a stoichiometric mixture ( theoretically 14.7:1, 12.5:1 in real world, for petrol ) of air and fuel is sent into the combustion chamber through it. The charge can be prepared by using a carburetor or a fuel injection system and controlled by using the throttle(accelerator). The air is taken from the atmosphere through an air-filter. We will present a separate article for this topic in a few days.

COMPRESSION STROKE

The second step is the Compression stroke. The Intake valve(s) is/are closed and charge is compressed by the piston, normally in the ratio 8 to 10:1 for petrol engines and 14 to 22:1 for diesel engines.

COMBUSTION STROKE

The third step is the Combustion stroke. There is a spark plug in the combustion chamber of engine which ignites the compressed charge and creates a blast, which pushes down the piston. The spark plug gets it electricity (upto 35000 volts) from the ignition coil which is controlled by an ignition system. Usually CDI(Capacitor Discharge Ignition) or TCI(Transistor Controlled Ignition) ignition systems are used in carbureted Motorbikes & Cars, whereas ECU (Engine Control Unit) is used in Fuel Injected Motorbikes & Cars. This is the actual step in which we get power from the engine. That’s why it is also called the power stroke.

EXHAUST STROKE

The fourth and last step is the Exhaust stroke in which the exhaust valve(s) is/are opened by the cam-shaft and the exhaust gases, which were created during power stroke, are expelled out of the engine through it and they pass through a platinum coated Catalytic Convertor, which converts these poisonous gases into other not-so-harmful compounds.

As you may have noticed, till now only an up-down motion of the piston is generated. This linear motion needs to be converted into rotational motion to drive the vehicle. Let us see how…

Motion Conversion

The piston is connected to a Con-Rod(short form of connecting rod) which in turn is connected to the crank-shaft. The crank-shaft is a device which converts the linear up-down motion of the piston into a usable rotational motion.

The Crank-shaft is connected to a Clutch system, which then connects to transmission (gear) system, with a reduction ratio of normally 3:1. This means that the transmission system rotates at about one-third of the speed of engine (rpms). This is called the Primary Reduction. A clutch is a device which can engage or dis-engage the transmission, as required by the rider/driver, by using a system of clutch plates(generally 4 or 5), Pressure plates(generally 3 or 4) and some springs (generally 4).

Each Pressure plate is sandwitched between two Clutch plates. It can be actuated either hydraulically or by using cables. The transmission converts the rotation for more torque (lower gears) or more power (higher gears) and provides the output through output shaft. As all the internal components of an engine are constantly sliding on each other, an engine oil is put inside the engine case for lubrication.

In motorcycles, a sprocket is connected to this output shaft, which in turn, is connected an another sprocket(usually larger) at the rear wheel. This means that the rear wheel rotates at a further reduced speed. This is called the Secondary Reduction. Normally it is around 3:1. This means that the rear wheel rotates at about one-third of the speed of the output shaft.

In a car, the output shaft connects to the front two, rear two or all the four wheels using a differential system (we will cover it later on). The differential reduces the rotational speed of output shaft and prevents the wheels of any one side from slipping while the car is taking a turn.

And that’s how an engine converts thermal energy into the car’s movement.

I hope you guys liked and understood my words. Feel free to express any questions that are in your mind and also help us to make this blog better.

Article by Ishan Dev

No comments:

Post a Comment